![]()

Rock of Ages Granite Quarry

September 2003

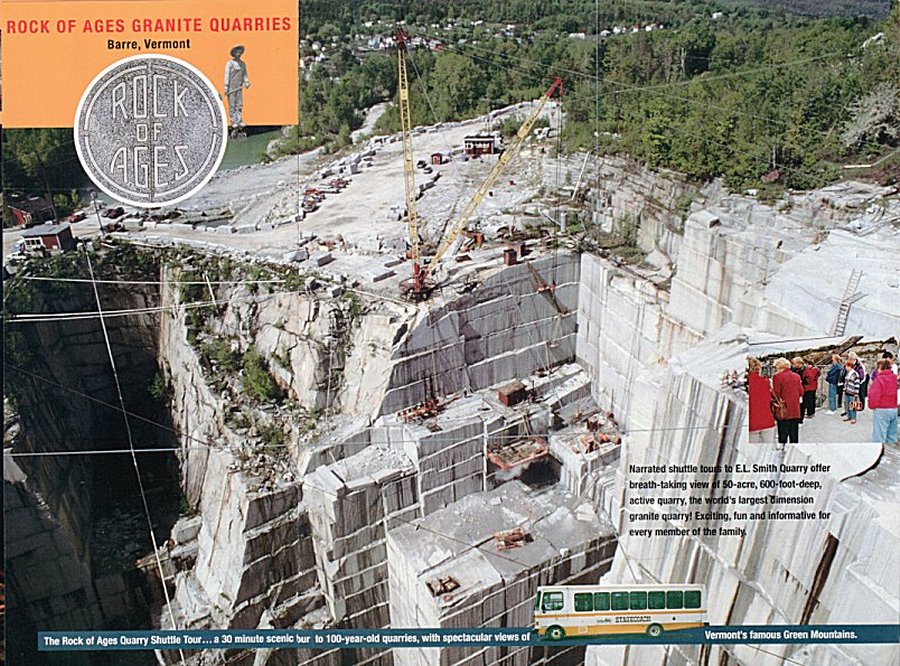

Founded in 1885, Rock of Ages is 50 acres, 600 feet deep and was built by native Yankees and by immigrants who came looking for a better life. |

![]()

![]()

Founded in 1885, Rock of Ages is 50 acres, 600 feet deep and was built by native Yankees and by immigrants who came looking for a better life. |

![]()

When the old timers quarried the granite back in the 1800's they used black powder instead of dynamite to

separate the granite blocks and because black powder is unpredictable in how it explods there was a 95% discard

of unusable granite and only 5% usable. They are now crushing these huge piles of unusable granite and spreading

it on roads, in driveways and also using it for making cement. They are also quarrying more granite for headstone,

signs, cutting boards, countertops, paper weights, etc., and will be able to do so for 50 more years (there's plenty!).

The blocks they remove are sold all over the world. We had fun going to nearby cemetery and seeing VERY unique

head stones - all dif shapes and designs (cube set on corner, 1/2 scale car, soccer ball, besides celtic crosses,

vines and Virgin Marys, etc.).

The guide was a retired school teacher and was very knowledgeable about the total operation and history which

made the tour great. The tour took about 45 minutes but the guide talked for the whole time, and when he came to

a lapse in the information someone would ask a question and he was off again. Excellent tour.

![]()

To view any picture on a larger scale just click on it.

Then click your browsers back button to return.